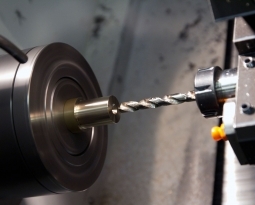

Subcontract CNC Milling

East Midlands based subcontract CNC milling and turning company Fastlathe Ltd, a long established manufacturer of precision components to the agriculture, automotive and grass cutting machinery sectors, has today put some of their latest CNC Milling products on show.

Machining using the latest Doosan and Dahlih lathes, our CNC Milling machining capabilities extend to a max bed size of 1020mm x 540mm.

Fastlathe have the capability to generate highly complex tool paths, using the latest advancements in CAM technology, to consistently deliver precision components to exacting standards.

John Davies, Shop Floor Manager at Fastlathe said “We can provide a wide range of products suited for the automotive industry including exhaust ends and accessories whilst using the latest CAD and CAM to fine detail utilising 3D drawings and models.”

Speaking of his companies CNC Milling facilities, Paul Horspool MD at Fastlathe said “We are really pleased to have the latest CNC Milling lathes along with our turning lathes that make the factory what it is today. Our highly skilled workforce combined with the latest CNC Milling technology allow us to produce precision machined components at competitive prices.”

Fastlathe are Subcontract CNC Milling and Turning specialists to the agricultural, automotive and grass cutting machinery sectors.

About Fastlathe

Established in 1978, Fastlathe are a CNC Machining company located in Langley Mill on the border of Nottinghamshire and Derbyshire supplying high quality subcontract engineering and powder coating services throughout the country.

Whether it’s CNC turned parts for the agricultural industry or a CNC milled part for a motorbike exhaust system, Fastlathe guarantee a fast and efficient service with no compromise on quality or delivery.

Exhaust Flange